The primary purpose of a safety valve is the protection of life, property and environment. A safety valve is designed to open and relieve excess pressure from vessels or equipment and to reclose and prevent the further release of fluid after normal conditions have been restored.

A safety valve is a safety device and in many cases the last line of defence. It is important to ensure that the safety valve is capable to operate at all times and under all circumstances. A safety valve is not a process valve or pressure regulator and should not be misused as such. It should have to operate for one purpose only: overpressure protection.

Reasons for excess pressure in a vessel

There is a number of reasons why the pressure in a vessel or system can exceed a predetermined limit. API Standard 521/ISO 23251 Sect. 4 provides a detailed guideline about causes of overpressure. The most common are:

- Blocked discharge

- Exposure to external fire, often referred to as “Fire Case”

- Thermal expansion

- Chemical reaction

- Heat exchanger tube rupture

- Cooling system failure

Each of the above listed events may occur individually and separately from the other. They may also take place simultaneously. Each cause of overpressure also will create a different mass or volume flow to be discharged, e.g. small mass flow for thermal expansion and large mass flow in case of a chemical reaction. It is the user’s responsibility to determine a worst case scenario for the sizing and selection of a suitable pressure relief device.

Main types of safety valves and their function

There are two main types of safety valves. Spring loaded safety valves and pilot operated safety valves.

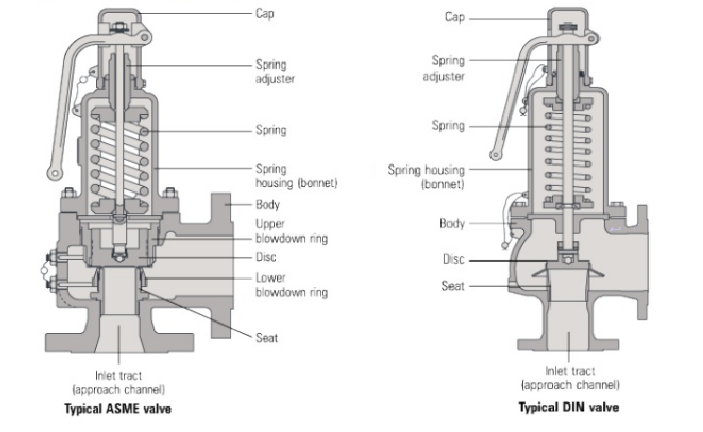

Spring loaded safety valves

The spring force is transmitted via the spindle to the plate closing against the nozzle, which together with the plate closes the process and ensures sealing. This condition is maintained as long as the spring force is greater than the force generated by the pressure at the valve inlet.

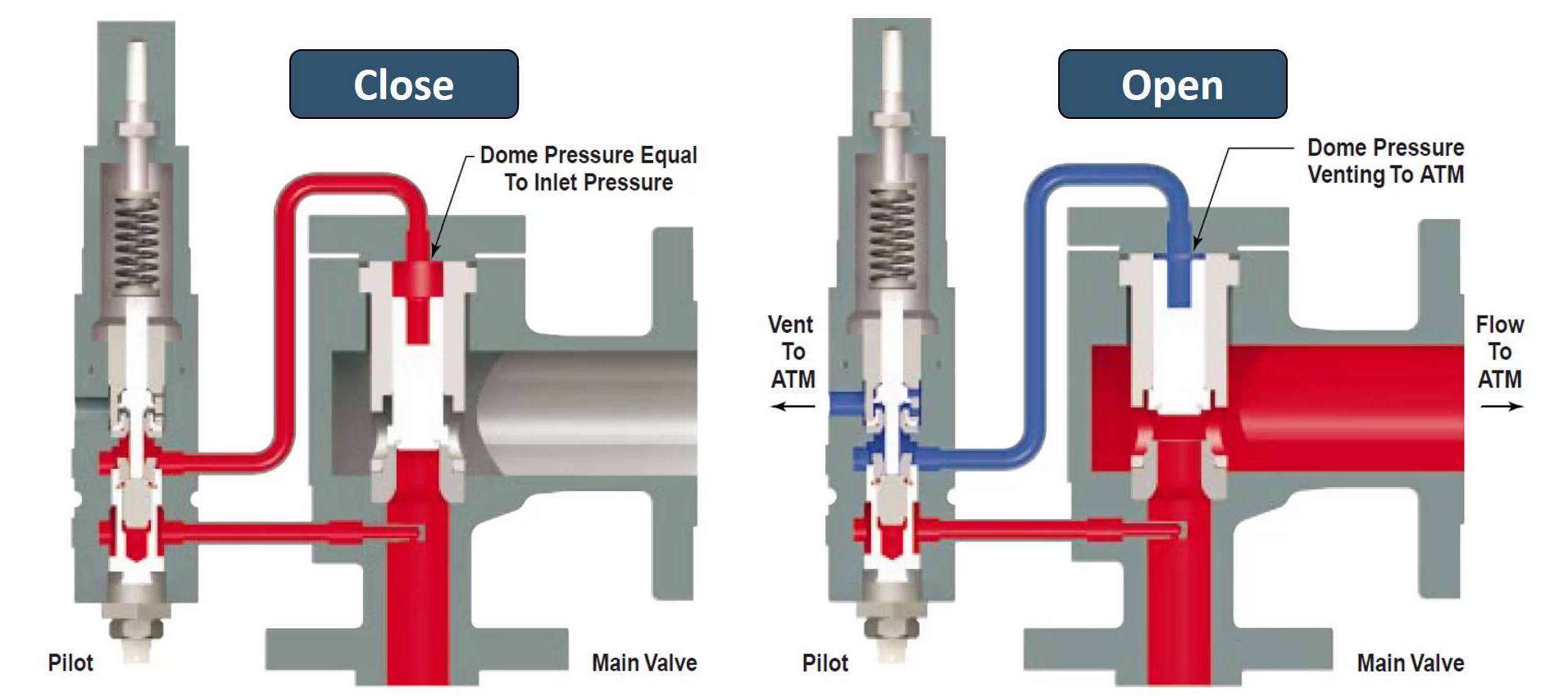

Pilot-operated safety valves

Pilot-operated safety valves limit the pressure in the system by compensating for the overpressure by opening the main valve. They are self-medium controlled and, as with all medium-loaded safety valves, the same pressures act on both sides of the sealing disc. However, a greater force acts in the closing direction due to surfaces of different sizes.