A ball valve consists of a valve body in which a large sphere with a central hole equal to the inside diameter of the pipe is mounted. As the ball is rotated, in the fully open position the valve provides the through conduit or full bore required for unrestricted flow of the fluid and scrapers or pigs. Compared with a gate valve, a ball valve has very little resistance to flow in the fully open position. When fully open, the L/D ratio for a ball valve is approximately 3.0. The ball valve, like the gate valve, is generally used in the fully open or fully closed positions.

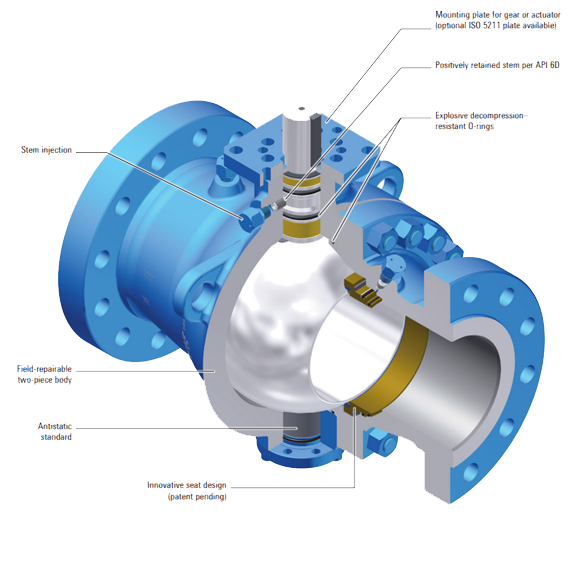

Operation is by rotation (1/4 turn) of a shaft mounted, often horizontally, with its axis at right angles to the cylindrical hole. Seals are usually resilient and can provide drop tight shut off. Ball valves are commonly used in small diameters (up to DN 300) although at least one manufacturer can make ball valves up to DN 1200. Ball valves are manufactured in one-piece, top entry, two-piece and three-piece bodies. A top entry body allows access to the ball and seats for maintenance without the need to remove the valve and is preferred for larger sizes.

Ball valves are widely used for large size piping in the subsea manifolds. In addition, small bore ball valves in size ½″ and ¾″ can be used in subsea distribution units on the piping system to be used for delivering chemicals and hydraulic oil.