Reverse engineering and spare parts construction

We're specialized in spare parts constructions for valves and mechanical components in general. The experience gained over time, in the solution of problems related to the valves of industrial plants has convinced us to start a service that goes beyond normal maintenance activities. In fact, to restore the functionality and efficiency of a valve, it is essential to replace worn or damaged components from corrosion; for this reason, immediate availability during maintenance is decisive.

In many cases, spare parts supplied by the customer are not compatible because they are obsolete, in other cases they are out of production or the procurement times can not be reconciled with the planning of maintenance operations. Moreover, with the thousands of valves present in a single plant, of a different manufacturer and type, this aspect assumes an even more important role. This criticality has repercussions on maintenance times in the event of unexpected damage and, moreover, the unavailability of a valve in good time may lead to plant downtimes in which the costs for non-production are not comparable with those of maintenance.

Reverse engineering is the process of extracting knowledge or design information by using 3D scanning data capturing system and redesign a used/new part of valve maker such as stem, trim, packing and so on.

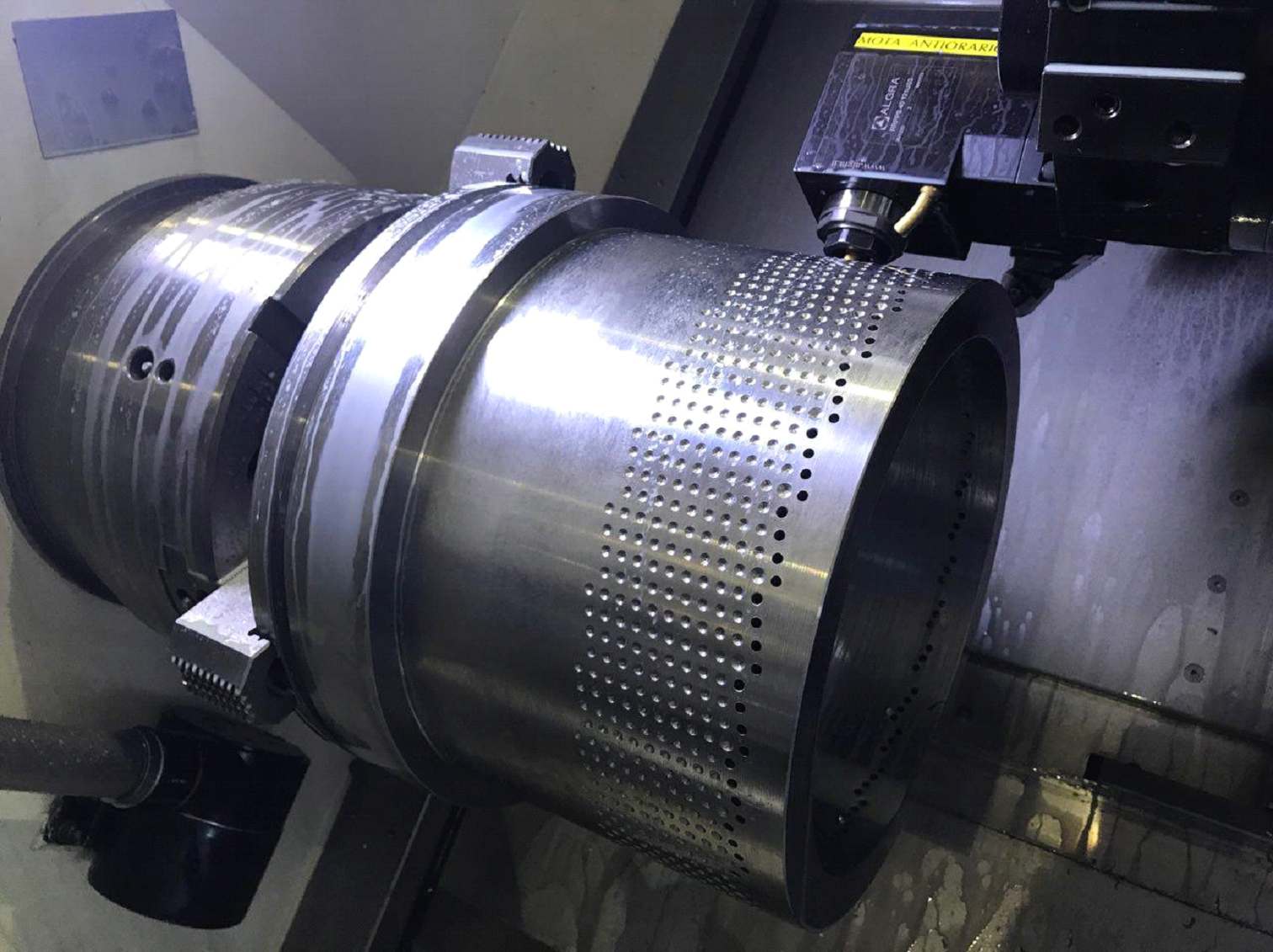

By undergoing reverse engineering, parts are not only be duplicated from the original but also improved and upgraded for better performance. The construction and precision of the build components is guaranteed attributed to the use of CNC multi-axis machining and turning centers, where the information extracted from the reverse engineering activity and the 3D modelling of the components to be built are perfectly integrated with production CAD/CAM system.

Cage

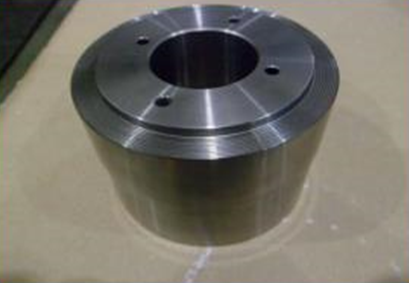

Guide

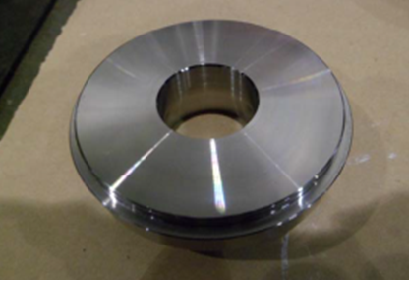

Trim parts

Plug with stem

Seat Ring